HOW CAN OPERATING COSTS IN SURFACE MINING BR REDUCE THROUGH DRILLING AND BLASTING OPERATION

This article is divided into the following subtopics:

1. What is mine operation cost?

2. Key factors that affect operation cost

3. Drilling and Blasting operation influence on operation cost.

4. How to optimize drilling and Blasting to minimize operation cost.

BRIEF ON MINE OPERATION COST

As a Mining Engineer working in a mine, we are all concerned about safety first then profit and constant cash inflow.

It obvious that, if their is no profit then there is crisis as this will be a tunnel to salary payment delay and even lost of our company customers.

"As continuity is the code of Continuous demanding"

MINE OPERATION COST: This is define as the total cost incur to produce a unit ton of an ore from the earth crust.

OPERATION COST IS DIVIDED INTO THREE

1. LABOUR COST

2. RAW MATERIAL COST

3. MISCELLANEOUS COST

1.Labour cost is the cost incur to compensate human effort as contribution to material production in the mine.

2. Raw material cost is the operation cost that includes all expenses incur to ensure all operation unit in the mine is operating efficiently. This includes diesel bought for loader, trucks, ANFO mixing, Tyre and equipments maintenance costs among others

3. miscellaneous cost are other cost put in place to ensure operation in the mine run smoothly and at high efficient rate. Thou may not be constant but are usually use to optimize productivity such as transport expenses from mine to city, food bought for labourer as compensation and to energies them. Having define and explain what mine Operation cost mean, I will like to submit to my readers that, this operation cost can be affected by various factors, various operating conditions.Miscellaneous cost is also known as overhead cost in economists term.

This is the money use

For other activities during production to enhance operation efficiency.

This can include the bonus given to worker due to extraordinary job done, money for recharge card to mobilize workers to the site among others)

It not usually constant per day or per ton of Run-off-mine produce per day.

Even though during the short run of any mine it understood that operation cost per ton of ore production is usually high why at long-run it usually low.

>>Then why do operation cost increase at the shortrun (start up stage) of a mine and reduce at the long-run (future stable stage) of a mine?

Let me quickly differentiate between operation cost and operating cost..

Operation cost is the total money budgeted to carryout an operation in the mine.

Why

Operating cost is the actual cost or money incur to ensure that an operation is successfully executed or carryout.

As a Mining Engineer planing to produce say 50Tons per day at a projected operation cost of $1 per Ton there is possiblity of poor Blasting reducing the production rate for days or possibility of water infiltration into the pit from aquifer or surface water inflow which may require dewatering operation, then increasing operation cost per ton to say $1.5 per ton.

The budgeted operation cost is $1 but the operating costs is $1.5

Mine project has two basic stages of production, technically and generally:

Short run stage and long run stage.

The short run stage is the starting point of a newly open mine. In this short run stage, the operation cost is usually very high and the mine is known to be at loss margin, most case low or no profit because operation cost is very high.

This is because various operations that dictates the operation cost amount are usually very capital consuming and of poor result.

what are the operations that factors and affect mine operation cost??

Professionally, a typical mine have 5 operation life cycle and each of this cycle influence the operation cost of the mine per day, per shift, monthly and yearly.

These operation cycles are:

1. Development operation.

2. Drilling operation,

3. Blasting operation.

4. Loading operation and

5. haulage operation

These five operations are carryout in a cyclic sequence through out the life of a typical mine.

You develop the deposit, drill holes into the formation, load the holes with exolosive, blast the hole to produce rock fragments, load the muckpile into dump truck, Transport or haul it to the processing plant.

Then development for a new drilling and blasting starts again....

This is why it is a cyclic operation and Continuous through out the mine life until the ultimate pit life is reached.

The five operations at short-run are usually capital intensive.

To start a new surface mine say open pit mine.

The cost of stripping the overburden at the beginning is so high and capital intensive compare to other developmental Operation including pit maintaining cost after every Blasting.

Likewise the first Blasting operation may produce high dilution rate due to intrusion or overburden caving or overbreak due to unavailability of mine face at the first Blasting.

The important of free face in Blasting control and efficiency is so important that we can't just bypass it, even if not sufficient we use box cut to create new at the rock mass center.

Likewise in case of a mine at short run, the first Blasting is called the face creation Blasting, it not usually productive, it includes more of external dilution. This and many other reasons makes a typical Quarry or mine to have low profit at short run stage.

Time won't permit I will have talk on haulage also, the ramp for the first bench is not usually of imperfect gradient, the fleet Design plan may likely not even work at the starting point of the mine it takes time to get the best design to make haulage work in a new mine.

You have more trucks queueing, sometimes the loader or excavator may need to separate the muckpile, select material base on size and even dilution control purpose by this under using the dump truck operation time.

Now, for long-run stage all the mine face had be created, the fleet Design formula had been perfected, good ramp gradient had been ultilize to efficiently transport run-off-mine to the mill, good blast Design had been Design with rule of thumb to avoid overbreak, external and internal dilution so time waste in selective loading can be minimized.

This is why, operating cost is usually low at long-run compare to short-run stage of any mine.

Since I have mentioned the basic operation factors affecting the variation of operation cost in the mine, i will dip into:-

How Drilling and Blasting operation affect Operation cost and how to optimize this operation to minimize operation cost.

It is not new to us as an engineer that rock is a combination of various Mineral and Mineral is a combination of various elements. This characteristic makes rock very Anisotropic (not having constant Strength all over) and heterogenous (not uniform both in composition and in physical and chemical property).

Also, we understand from scholars research that rock expecially the igneous and metamorphic are of high Uniaxial compressive strength due to their thermogenesis and metagenesis origination.

And we as a Mining Engineer, we befriend rock mass to win the ore (occurrence of Mineral accumulation with economic use).

To win this ore we need to librate the rock mass so we can convey only the concentrate (valuable) material to the Mineral processing plant for comminution (crushing and grinding operation) and Separation process.

As a Blasting Engineer we aim at using the best Explosive quantity to break down the rock mass into transportable sizes which requires less loading and milling operation.

When a Blasting Engineer failed to produce good fragmentation it automatically increase the mine operation cost.

This is very serious and imperative unlike other operations, drilling and Blasting don't just increase the mine operation cost but also increase the milling and mineral processing cost.

Starting from drilling operation and it's effect on Blasting and then on operation cost...

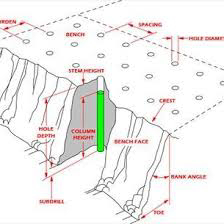

Selection of small drill hole diameter reduce the Burden and spacing of Drillholes, it reduces the Drilling depth and then increase the number of drill hole per Blasting.

Let me prove this shortly using Langford or rule of thumb formula to design a blast with two different hole diameters.

Considering two Blasting:

Hole 1: diameter is 0.004m (jack hammer drill machine)

Hole 2: diameter is 0.065m (say wagon drillhole)

For hole 1:

Using rule of thumb

Burden (B)=25-45*hole diameter (using 30*d)

B=30*0.04

Burden=1.2m

Spacing=1.15*B (staggered pattern)

S=1.15*1.2

S=1.38m

For hole 2:

Using rule of thumb

Burden (B)=25-45*hole diameter (using 30*d)

B=30*0.065

Burden=1.95m

Spacing=1.15*B (staggered pattern)

S=1.15*1.95

S=2.24m

Assuming we are to Blast a bench of 25m by 25m

The implementation of this two holes diameter is that,

For hole 1, more hole will be drill on the bench Why for hole two, less holes will be drilled:

Let proof that also

For hole 1

Number of hole per column (Nc)= bench area÷Bench

Nc =(25m*25m)/1.2

Nc=625/1.2

Nc=521holes

Numbers of holes let row on the bench (Nr)=Bench area/spacing

Nr= 625/1.38

Nr=453holes per row

Total holes to be drill is Nr*Nc

Total hole= 236,013 holes.

For hole 2

Number of hole per column (Nc)= bench area÷Bench

Nc =(25m*25m)/1.95

Nc=625/1.95

Nc=321holes per column

Numbers of holes let row on the bench (Nr)=Bench area/spacing

Nr= 625/2.24

Nr=279holes per row

Total holes to be drill is Nr*Nc

Total hole= 89,559 holes.

The implementation is that the diameter affect both spacing and burden, it affect the number of holes drilled.

Imagine a different of 146,454holes between the two hole diameter.

More hole means more working days to carryout Drilling operation, more working days implies more diesel consumption per day, more operator allowance per day, more equipment cost per day..

This affect operation cost directly without any measure.

Drilling accuracy of drillhole collar and column also affect the efficiency of Blasting, it create problem in the stope after Blasting.

Poor drilling accuracy affect the distribution of Explosive Energy withing the hole thereby resulting into

1.poor fragmentation

2. Generation of flyrock

3. Overbreak

4. Ground vibration and others

1.Poor fragmentation increase operation cost by prolonging loading time. Loading time prolonged result into decrease in production per day.

Less material will be move from the mine to the mill.

More diesel will be waste as the loader tries to separate oversize boulders to load optimum size.

2.Generation of flyrock can cause damage to equipment, house and even break someone's head leading to total close down of the mine. Damage to equipment will cost more money, why breaking of someone's head or causing injury can cost the company weeks of no work or total closure of the mine which can be open after payment of compensation and diver fine if license is not withdraw from mine operator.

3.Overbreak directly weakens the bench wall and may lead to plane or wedge failure. Sliding down of rock mass on workers will be a disastrous senario, also closure of pit will cost high development cost, you know high cost of equipment for loading sand and debris, high cost of moving waste out of the mine...

4. Likewise ground vibration distabilies structure, cause disturbance to nearby fellows which can lead to submission of petition against your company...

Also, if the mine site location is closed to the earth tectonic plate edge region possibility is that earthquake may surface or land subsidence...

Drilling and Blasting operation really affect operation cost a lot.

Beyond that it affect milling and process cost for both metallic and non metallic Minerals.

Poor Blasting is define by me as that which generate environmental illness like airblast, ground vibration, flyrock among others and that Blasting which produce poor fragmentation with poor loading processing efficiency.

When a Blasting is confirmed to be a poor Blasting, it increases overbreak, increase dilution rate and also subject other downstream operations into chaos.

In case of metallic ore, production of external dilution due to overbreak and internal dilution due to backbreak not only cause a delay in loading and increase in mine operation cost, it also increase the cost of milling, increase the cost of separating the gangue (waste materials, barren rocks, host rocks) from the run-off-mine.

This not only affect the operation cost it gradually increase the mine life, it affect the mine capital payback period, reduce the company productivity Net present value.

Payback period is the schedule time for a mine or any business to return the initial investments back and begin to make profit.

Net present value NPV is a project Profit analysis tool use to compare the present value of the initial capital cost of a project to the present value of the cash inflow.

Having more diluted run-off-mine affect the profit margin of a mine beyond just affecting operation cost

So as a mining and Blasting Engineer we need to hold our position well and plan well to ensure we deliver a good blast that will not just be safe but also profitable to load, transport and Mill to process.

It confirmed that initiation pattern with poor timing will also create problem to blast result,

Likewise poor burden distance, poor stemming length, poor Explosive selection among others.

Having misfire is also another problem that will affect operation cost of a mine.

How can drilling and Blasting be optimize to minimize operation cost?

I have answered this question in my words above indirectly.

But I will stretch my time to give clear rib support and crown pillar support to the answer (Don't mind I just go underground to borrow terminology)

To Carry out a good Blasting, there are three things you need to know and implement:

1.Proper Blast Pre-planning

2. In charge planing

3. Post Blasting planing

1.Pre-planning include:

a.understanding the Rock material

b. Mapping of rock formations to understand the discontinuity condition

c.selection of best blast Design and blast parameters (hole diameter, burden, spacing, Stemming length, bottom charge length and weight, column charge length and charge weight, powder factor e.t.c) all this are very important.

d. Selection of best Explosive with the sufficient property to function at the blast location

e.selection of best drilling machine Among others

Taking a sharp look at powder factor:

it is the economic control loop for Blasting operation, it determine the quantity of explosive you will use and the cost to fragment a ton of the ore.

If powder factor is high that implies that more Explosive will be purchase, operation cost will increase.

If powder factor is low, poor fragmentation is certain, increase in loading cost and haulage cost.

All this parameters must be optimzed and balance.

If burden distance is large, poor fragmentation is certain, as this dictates the rate of tensile slabbing at the Explosion CJ plane. If burden distance is to much the shock wave will not complete micro-fracturing before the gas Energy is release meaning more of oversize material will be produced..

All the parameters are important, as blast Engineer we should consider balancing them with the uncontrollable factor of the rock (Uniaxial compressive strength, rock elasticity, discontinuity nature, and rock geotechnical properties)

2.In charge planing:

This is an action control measure.

There are basically three key elements of production optimization and safety garantee in a mine.

1. Engineering level: This involves blast design and preparation.

2. Education: this includes educating and training personnel on how to implement the blast Design on site to provide the expected result.

3. Enforcement: human will always be human as we are not machine, you need to supervise workers to ensure complete and correct implication of Design.

No oversight supervision, no unsafe act supervision.

All Blasting operation stages are well monitored and supervise by competent Engineer..

If poor Stemming length or material is used, you have pull out and other poor result from Blasting operation.

If workers decided to steal Explosive and Blasting accessories then use low quantity material due to your absence on site, this is directly going to affect Blasting output an increase production cost

Finally, the post Blasting plan include checking out the blast result and making proper plan and recommendation for next Blast operation.

In conclusion:

As a Mining Engineer or mine company CEO reading this article, the best way to minimize operation cost is to plan, implement and supervise the implementation on site.

Blasting is for safety and not for damage.

Thanks for reading

Kindly subscribe and share with friends.

® GIANT MINER

Committed to advancing mining knowledge.....