Blast-induced fly rock generation occurs when rock fragments are thrown beyond the blast area, posing safety risks [1-3]. Causes include inadequate blast design, excessive explosive charge, or poor stemming. Control measures involve proper blast design, use of suitable explosives, adequate stemming, and implementing safety zones to minimize fly rock hazards. Preventing flyrock in blasting involves careful parameter design and analysis, including WipFrag analysis. Here are key steps:

1. Blast Design:

Ensure a well-designed blast pattern, considering rock properties and site conditions.

Optimize burden (distance between blastholes) and spacing (distance between rows of blastholes) based on rock type and desired fragmentation.

2. Explosive Selection:

Choose explosives that match the rock type and desired fragmentation.

Avoid excessive explosive charges that could lead to uncontrollable energy release.

3. Blasthole Design:

Use proper hole diameter and depth based on geological conditions.

Ensure uniform loading of explosive material in blastholes.

4. Stemming Material:

Employ adequate stemming (material placed on top of explosives) to confine energy and reduce flyrock.

Verify stemming height is appropriate for the blast.

5. WipFrag Analysis:

Use WipFrag analysis to assess fragmentation results post-blast.

Analyze particle size distribution to fine-tune blast parameters for optimal results.

6. Monitoring and Adjustments:

Continuously monitor and analyze blast performance.

Make adjustments based on monitoring data and feedback to improve future blasts.

7. Safety Zones:

Establish safety zones and clear blast areas to prevent injuries or damage in case of unexpected flyrock.

8. Training and Compliance:

Ensure personnel involved in blasting are well-trained and adhere to safety protocols.

Comply with local regulations and industry standards related to blasting operations.

By integrating these steps into the blasting process, you can mitigate the risk of flyrock and optimize fragmentation for better overall blasting efficiency.

Understanding Delay Timing and initiation approach for Flyrock control

This approach involves the use of primer placement or heavy charge Technique to prevent Flyrock generation.

The location of the primer is important, and as well as the status of the charge density along the hole column.

Firstly, having heavy charge close to the hole collar promote Flyrock generation as well as placing primer or booster closer to the surface.

A primer usually consists of a detonator and a boost containing initiation explosive [1]. A primer is often used to initiate a commercial explosive charge in a blasthole. Sometimes a detonator can be also used to directly ignite an explosive charge. Thus, detonator placement is the same thing as primer placement. The position of a primer in a blasthole plays an important role in rock fracture, fragmentation, and even ore recovery. Unfortunately, this important role has been not well understood so far. As a consequence, an improper or even wrong primer position can often be found in present engineering blasting. The

role of primer position in blasting can be found from various aspects, such as detonation energy, stress distribution, rock

fragmentation, ore extraction, productivity, and safety [1, 2]

Implement delay timing in the blast sequence to control energy release and avoid simultaneous detonation, reducing flyrock risks.

The primer charge Initiation is the giver of wave front direction and the dictator of how well the blast will go. When the primer is located at the

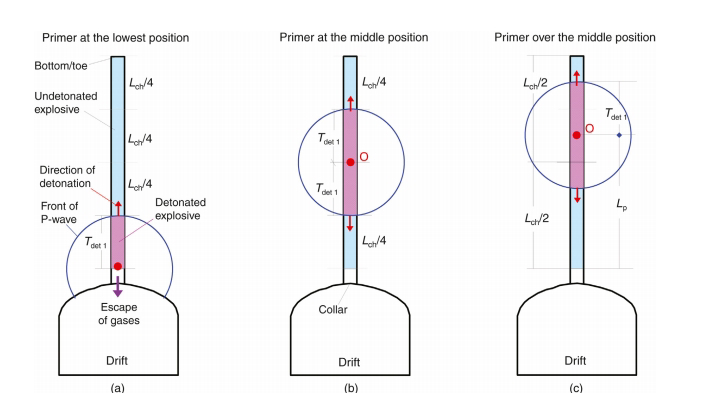

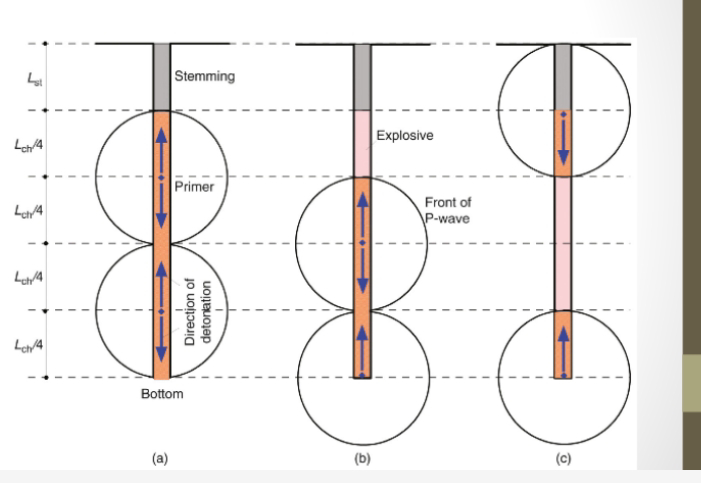

Fig.1 shows an explanation of how the initiation of blast using three placement point. Fig.2 shows the wave front movement after initiation.

Fig. 3 Resulting Blast

From Fig.1, If only one primer is placed in a borehole, the primer can be placed at different positions. In order to simplify the analysis, we take three cases to discuss: (a) middle primer, (b) bottom primer, and (c) top primer

In the case of two primer position: (a) two primers at the one-fourth and three-fourths length of the charge; (b) two primers, one at the bottom and the other at the middle; and (c) two primers, one at the bottom and the other at the top. Among these cases, case (a) is the best, case (c) is the worst and should be avoided, and case (b) is in between [6-7].

Conclusion:

Flyrock Generation is one of the hazardous product of blasting. It occurs when the Explosive energy is excessive and when the charge energy is excess at the hole collar. This can be as a result of using insufficient stemming length, less confinement, to small Burden and poor initiation system.

Understanding the behavior of wave Generated during initiation had been explained in this article. The article provide insight from published material, and gives recommendation on primer Placement and charge rate along blast hole collar.

The rock resistance reduced along weak zone and less burden region, when the Explosive charge increases, the breaking factor increases. In a case where excess energy is available, it is use for the throwing of rock particles, thereby causing damage to structures, building, human, and equipments.

References

1. Dick, R. A., Fletcher, L. R., & D'Andrea, D. V. (1983). Explosives and blasting procedures manual (No. 8925). US Department of the Interior, Bureau of Mines.

2. Meyer, R., Köhler, J., & Homburg, A. (2008). Explosives. John Wiley & Sons.

3.Taiwo, B. O., Hosseini, S., Fissha, Y., Adebayo, B., Adesida, P. A., Famobuwa, V., ... & Akinlabi, A. A. (2023). Safe small scale mine blasting operation: An application of soft computing techniques to predict blast-induced flyrock distance.

4. Zhang, Z. X. (2014). Effect of double-primer placement on rock fracture and ore recovery. International Journal of Rock Mechanics and Mining Sciences, 71, 208-216.

6. Morante, E. A. (1987). A primer on placement testing. New Directions for Community Colleges, 1987(59), 55-63.